|

|

SINO-NSH VR SeriesVacuum Pump Set (Air Evacuating)

Also named: vacuum pumps, vaccum pumping system, two stage vacuum pumps, transformer evacuation, etc.

Function: Evacuation for facilities

Flow Rate: 100-3000 m3/Hour Power Supply: 380VAC / 3Phase / 50Hz (or tailorable to yours) Delivery Time: 10 working days Supply Ability: 50 sets per month |

PRODUCT OVERVIEW

|

A continually increasing number of applications in industry and research are relying on vacuum technology. Thus widely differing requirements result regarding the vacuum generating systems.

Based on the long-standing experience in the design and manufacture of vacuum pump systems, NSH offers standardized pump systems which will match most applications – the VR pump systems. Typical areas of application for SINO-NSH VR pump systems are industry, research and chemistry. Here the focus is on processes for metal production and processing, drying and degassing, thermal treatment, coating in the area of semiconductor manufacture as well as surface refinement. VR pump systems are also used as backing pump sets for high vacuum systems in combination with diffusion pumps, turbomolecular pumps and cryo pumps. |

BENEFITS:

|

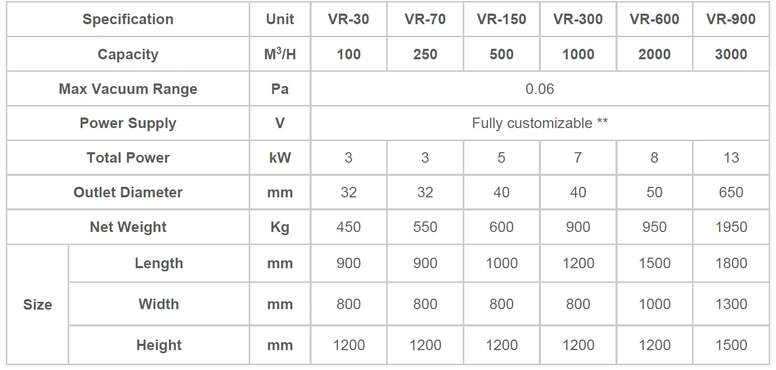

MACHINE SPECIFICATION:

MACHINE OPTIONS:

- Base frame with caster wheels

- Metallic enclosure cover on caster wheels

- Metallic enclosure cover on single axle trailer

- Base frame on double axle trailer

- Metallic enclosure cover on double axle trailer

- Metallic enclosure cover and operation room on double axle trailer

Other Resources > Transformer Oil Purifier -Double-Stage Vacuum Purifier -Full-automatic Double-Stage Vacuum Purifier -Single-Stage Vacuum Purifier -Double-Stage Vacuum Regeneration > Vacuum Oil Purifiers -Hydraulic Oil Purifier -Turbine Oil Purifier -Phosphate Ester Fuel-resistant Oil Purifier > Transformer Maintenance Equipment |